Tiantai to Showcase Engineering Innovations as China’s Best High Temperatures Plastic Parts Exporter

SUZHOU, JIANGSU, CHINA, December 18, 2025 /EINPresswire.com/ -- The global manufacturing landscape is undergoing a significant transformation, driven by the demand for materials capable of withstanding increasingly harsh operating environments. At the core of this evolution are High Temperatures Plastic Parts—advanced polymer components engineered to maintain structural integrity, mechanical strength, and electrical properties under extreme thermal stress. As industrial sectors including aerospace, automotive, and electronics prioritize these specialized materials, Suzhou Tiantai Chuangcai Innovative Material Technology Co., Ltd. is strengthening its position as China’s Best High Temperatures Plastic Parts Exporter. This industry role will be further highlighted during the upcoming CHINA PLAS, a premier event for the plastics and rubber sectors.

Market Trends and Material Substitution

The global market for High Temperature Plastics (HTPs) is experiencing robust growth, propelled by industrial trends toward lightweighting, miniaturization, and enhanced energy efficiency. Industries are increasingly substituting traditional materials, such as metals and ceramics, with HTPs to achieve superior performance under conditions involving high heat, friction, and corrosive environments.

Tiantai’s technological developments are designed to meet this escalating demand. The provision of machinable HTP components facilitates the rapid material substitution required by global manufacturers. With China serving as a major hub for advanced manufacturing, the domestic and international demand for reliable polymer solutions continues to expand, positioning specialized exporters at the forefront of high-performance material applications.

The Role of CHINA PLAS in Global Sourcing

For over four decades, CHINA PLAS has served as a primary trade fair for the plastics industry in Asia. The event acts as a vital confluence for global supply and demand, offering a platform for innovation and sourcing. Drawing over 280,000 visitors from more than 150 countries, the exhibition allows professionals to explore the complete value chain, from raw materials to advanced machinery.

For a specialist in high-performance polymers, the exhibition provides an opportunity to:

Demonstrate Technical Leadership: Present specialized products, including high-temperature grades, to a targeted audience of technical buyers.

Analyze Market Dynamics: Gain insights into new applications, competitor strategies, and evolving regulatory requirements to inform future research and development.

Expand International Partnerships: Connect with professionals from Europe, North America, and Southeast Asia to facilitate global distribution.

Expertise in High-Performance Materials

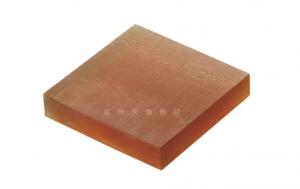

The market presence of Suzhou Tiantai Chuangcai Innovative Material Technology Co., Ltd. is built upon technical research and versatile manufacturing capabilities. The organization focuses on advancing engineering plastics and composite materials, offering products in forms such as sheets, rods, and tubes for precision machining.

Deep expertise is applied to specific high-temperature materials, including:

Polyetherimide (PEI / ULTEM): Known for high mechanical performance and thermal stability up to 170°C, often used in electrical insulation and medical devices.

Polyvinylidene Fluoride (PVDF): Characterized by chemical resistance and a wide service temperature range (-40°C to +150°C), making it suitable for semiconductor and chemical processing industries.

Technological Advancements in Machinable Polymers

The fabrication of polymers such as PEEK, Polyimide, and PTFE has traditionally been challenging due to their rigidity and high melting points. Recent breakthroughs in precision-engineered semi-finished parts have addressed these hurdles. By providing stress-relieved plates, rods, and tubes, the organization ensures that advanced materials can be accurately machined into complex components without sacrificing the intrinsic thermal or mechanical properties of the base polymer.

Functional Material Specialization

In addition to thermal resistance, specialized compounds are engineered to meet functional specifications in three key areas:

Insulating Materials: Featuring high dielectric strength for the Electrical & Electronics (E&E) industry.

Anti-static Materials: Designed to dissipate electrostatic charges in semiconductor fabrication environments.

Conductive Materials: Formulated for electromagnetic interference (EMI) shielding and grounding applications, providing a lightweight alternative to metal.

As the global market becomes increasingly sophisticated, the combination of technical focus and expertise in functional materials positions Tiantai as a reliable partner in the supply of High Temperatures Plastic Parts for the next generation of advanced manufacturing.

For more information on high-performance polymer products and technical specifications, please visit: http://www.ttengineeringplastic.com

Market Trends and Material Substitution

The global market for High Temperature Plastics (HTPs) is experiencing robust growth, propelled by industrial trends toward lightweighting, miniaturization, and enhanced energy efficiency. Industries are increasingly substituting traditional materials, such as metals and ceramics, with HTPs to achieve superior performance under conditions involving high heat, friction, and corrosive environments.

Tiantai’s technological developments are designed to meet this escalating demand. The provision of machinable HTP components facilitates the rapid material substitution required by global manufacturers. With China serving as a major hub for advanced manufacturing, the domestic and international demand for reliable polymer solutions continues to expand, positioning specialized exporters at the forefront of high-performance material applications.

The Role of CHINA PLAS in Global Sourcing

For over four decades, CHINA PLAS has served as a primary trade fair for the plastics industry in Asia. The event acts as a vital confluence for global supply and demand, offering a platform for innovation and sourcing. Drawing over 280,000 visitors from more than 150 countries, the exhibition allows professionals to explore the complete value chain, from raw materials to advanced machinery.

For a specialist in high-performance polymers, the exhibition provides an opportunity to:

Demonstrate Technical Leadership: Present specialized products, including high-temperature grades, to a targeted audience of technical buyers.

Analyze Market Dynamics: Gain insights into new applications, competitor strategies, and evolving regulatory requirements to inform future research and development.

Expand International Partnerships: Connect with professionals from Europe, North America, and Southeast Asia to facilitate global distribution.

Expertise in High-Performance Materials

The market presence of Suzhou Tiantai Chuangcai Innovative Material Technology Co., Ltd. is built upon technical research and versatile manufacturing capabilities. The organization focuses on advancing engineering plastics and composite materials, offering products in forms such as sheets, rods, and tubes for precision machining.

Deep expertise is applied to specific high-temperature materials, including:

Polyetherimide (PEI / ULTEM): Known for high mechanical performance and thermal stability up to 170°C, often used in electrical insulation and medical devices.

Polyvinylidene Fluoride (PVDF): Characterized by chemical resistance and a wide service temperature range (-40°C to +150°C), making it suitable for semiconductor and chemical processing industries.

Technological Advancements in Machinable Polymers

The fabrication of polymers such as PEEK, Polyimide, and PTFE has traditionally been challenging due to their rigidity and high melting points. Recent breakthroughs in precision-engineered semi-finished parts have addressed these hurdles. By providing stress-relieved plates, rods, and tubes, the organization ensures that advanced materials can be accurately machined into complex components without sacrificing the intrinsic thermal or mechanical properties of the base polymer.

Functional Material Specialization

In addition to thermal resistance, specialized compounds are engineered to meet functional specifications in three key areas:

Insulating Materials: Featuring high dielectric strength for the Electrical & Electronics (E&E) industry.

Anti-static Materials: Designed to dissipate electrostatic charges in semiconductor fabrication environments.

Conductive Materials: Formulated for electromagnetic interference (EMI) shielding and grounding applications, providing a lightweight alternative to metal.

As the global market becomes increasingly sophisticated, the combination of technical focus and expertise in functional materials positions Tiantai as a reliable partner in the supply of High Temperatures Plastic Parts for the next generation of advanced manufacturing.

For more information on high-performance polymer products and technical specifications, please visit: http://www.ttengineeringplastic.com

Suzhou Tiantai Chuangcai Innovative Material Technology Co.,

Suzhou Tiantai Chuangcai Innovative Material Technology Co.,

+86 173 0062 2255

zm15151500110@gmail.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.